standard hardness test|rockwell hardness tester diagram : online sales In order to avoid misinterpretations of the perceived hardness, the standards prescribe a certain distance between multiple indentations. Examples of indent spacing in the Vickers hardness test for metallic materials . . For the Knoop hardness test, the two halves of the long diagonals must not differ by more than 10.0% from each other.

Número de linhas de pagamento (number paylines): 243 WTW; RTP (Return to Player/Quota de Reembolso): 97.22%; Maior ganho: 100000; Desenvolvido por: Tema de galinhas; Golden Slot. Golden Slot possui 5 rodas e incríveis 243 formas de vencer, o que dá ao jogador uma grande probabilidade de ser premiado e sair no lucro.

{plog:ftitle_list}

Resultado da 2 de set. de 2023 · Today we are going to tell you about Bet365 and competitive advantages. Bett-Market provides free consultations related to sports betting software, and it .

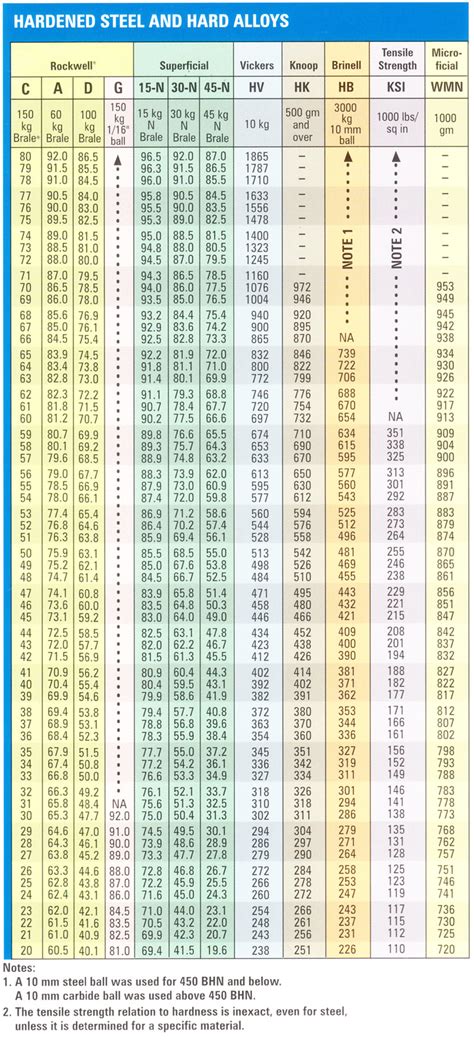

Listed below are common American Society for Testing and Materials (ASTM) standards that reference hardness testing. Newage Testing Instruments recommends that you obtain a copy of the appropriate standard for your application and that you read and .The Rockwell hardness test method, as defined in ASTM E-18, is the most .

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .In order to avoid misinterpretations of the perceived hardness, the standards prescribe a certain distance between multiple indentations. Examples of indent spacing in the Vickers hardness test for metallic materials . . For the Knoop hardness test, the two halves of the long diagonals must not differ by more than 10.0% from each other.

The widely used standards for the Brinell Hardness Test in industries are: ASTM E10: ASTM E10 specifies the test method for the Brinell hardness of materials, ensuring consistency and reliability in testing across various industries. ISO 6506: The Brinell hardness test is standardized under ISO 6506. This standard outlines the testing .

The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance: Ideal for micro hardness .2340 HARDNESS* 2340 A. Introduction 1. Definition Originally, water hardness was understood to be a measure of . *Approved by Standard Methods Committee, 1997. HARDNESS (2340)/EDTA Titrimetric Method 2-37. intended as a rough guide only and are based on .

Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific varieties of a hardness test determined by factors such as the type of indenter, applied force, and procedure of force application. .

The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and . Standard Test Method for Film Hardness by Pencil Test D3363-22 ASTM|D3363-22|en-US Standard Test Method for Film Hardness by Pencil Test Standard D3363 Standard Test Method for Film Hardness by Pencil Test> new BOS Vol. 06.01 Committee D01 $ 61.00 In stock Significance and Use.

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .It is applied to the specimen with a test force (to standard from 1 kg to 3000 kg) and held according to the holding time. To calculate the Brinell hardness, two perpendicular diameters of the test indentation are measured on the specimen surface. In addition, the test force N and the diameter of the spherical indenter are required.

1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable .ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals.

NIST Rockwell SRMs are transfer standards intended for use in the calibration and verification of the performance of hardness equipment using the Rockwell C and N Hardness Scales (HRC and HRN). NIST Microindentation Hardness SRMs are for use in calibrating and checking the performance of microhardness testers using the Knoop and .Metallic materials — Rockwell hardness test — . International Standard 6508-1 was prepared by the Technical Committee ISO/TC 164, Mechanical testing of metals, Subcommittee SC 3, Hardness testing. This first edition of ISO 6508-1 cancels and replaces ISO 6508:1986 and ISO 1024:1989, of which it constitutes a .ISO 6508-1:2015 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic materials and is applicable to stationary and portable hardness testing machines.

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.

The Rockwell test is described in ASTM E18 – 20 (Standard Test Methods for Rockwell Hardness of Metallic Materials). Vickers Hardness Test The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation.3.1.4 Rockwell superficial hardness test—same as the Rock-well hardness test except that smaller preliminary and total test forces are used. 3.1.5 verification—checking or testing to assure conform-ance with the specification. 4. Significance and Use 4.1 The Rockwell hardness test is an empirical indentation hardness test.

In hardness testing, there are inherent variables that preclude using standard Gage R&R procedures and formulas with actual test pieces. Material variation and the inability to retest the same area on depth measuring testers are two significant factors that affect GR&R results.The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). . The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an .In this revision the requirement of method for Rockwell superficial hardness test, calibration of standardized blocks and verification of Rockwell hardness testing machines have been included. In the preparation of this standard, assistance has been drawn from ASTM E 18 -97a ‘Standard test methods for Rockwell hardness and Rockwell Durometer is a standard in industry for measuring the hardness (or indirectly, modulus) of a material . Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to measure it. Hardness is used as a qualitative basis for material comparison, .

Read the applicable ASTM standards and contact a Paulo metallurgist to discuss hardness testing methods. Our commitment to educating customers has been a key to our success over 75 years in business , and illustrates how outsourcing heat treatment can add value to your business.Institute (NMI) for hardness, and as such, is responsible for traceability in hardness measurements. Objective Impact and Customers • Hardness is the most commonly used industrial test for quality control and acceptance testing of metals and metallic products. • Of over 12 000 ASTM standards, hardness test method standards are

rockwell hardness testing chart

rockwell hardness tester diagram

19 de abr. de 2023 · Cartão amarelo, vermelho, pênalti e escanteio: veja quais eram os lances exigidos para jogadores alterarem o rumo dos jogos . Se o pênalti fosse marcado - o que não aconteceu -, ele .

standard hardness test|rockwell hardness tester diagram